We welcome your support – DONATE NOW!

New Materials

Can exploring new materials change how we engineer our highways?

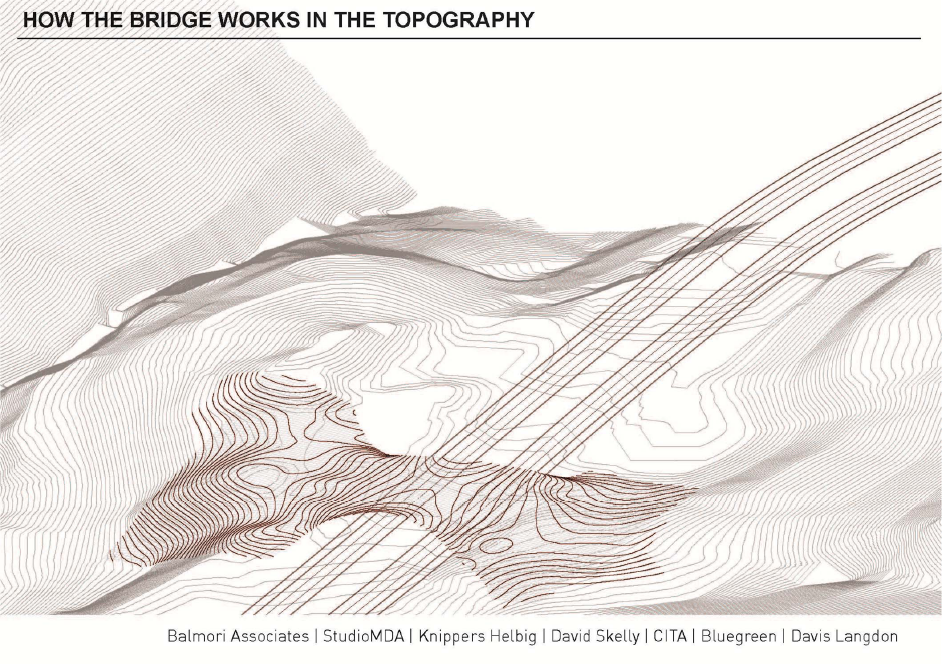

Wildlife overpasses are the reverse of most conventional bridges in terms of structural engineering, and this has implications for how they are designed and the materials from which they can be made.

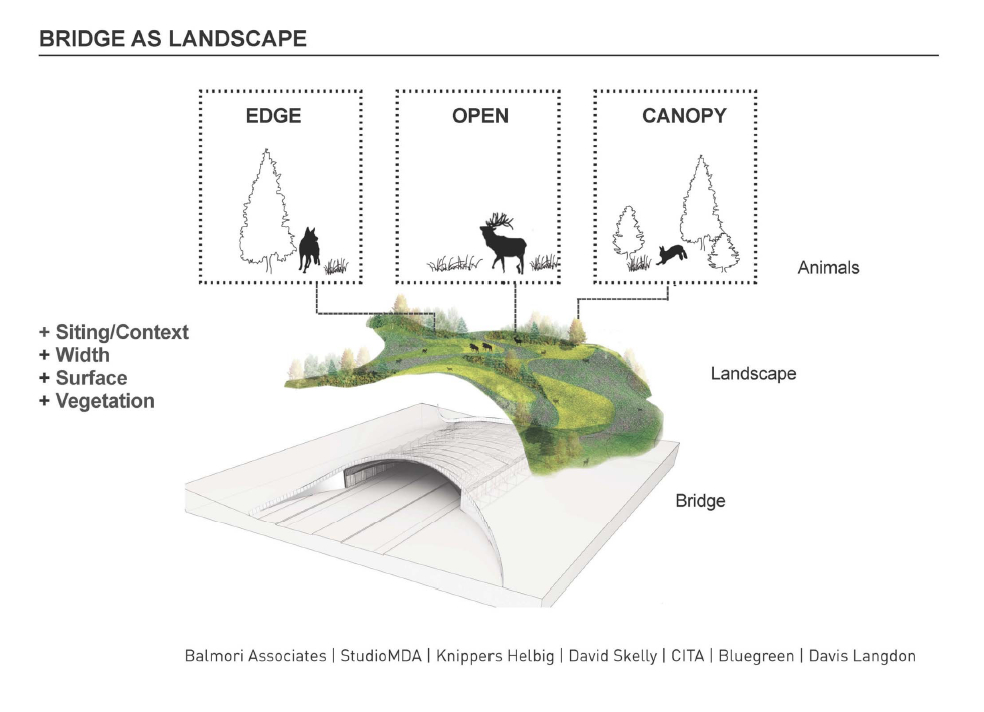

Conventional vehicular bridges are typically longer in span than width; that is, they are narrow enough to accommodate maybe two to four lanes of traffic but may have a long span to cross a river, a highway or a harbour. Wildlife bridges are typically shorter in span but much wider. They also necessarily include a thick layer of soil and vegetation—a landscaped surface—that must emulate local habitats.

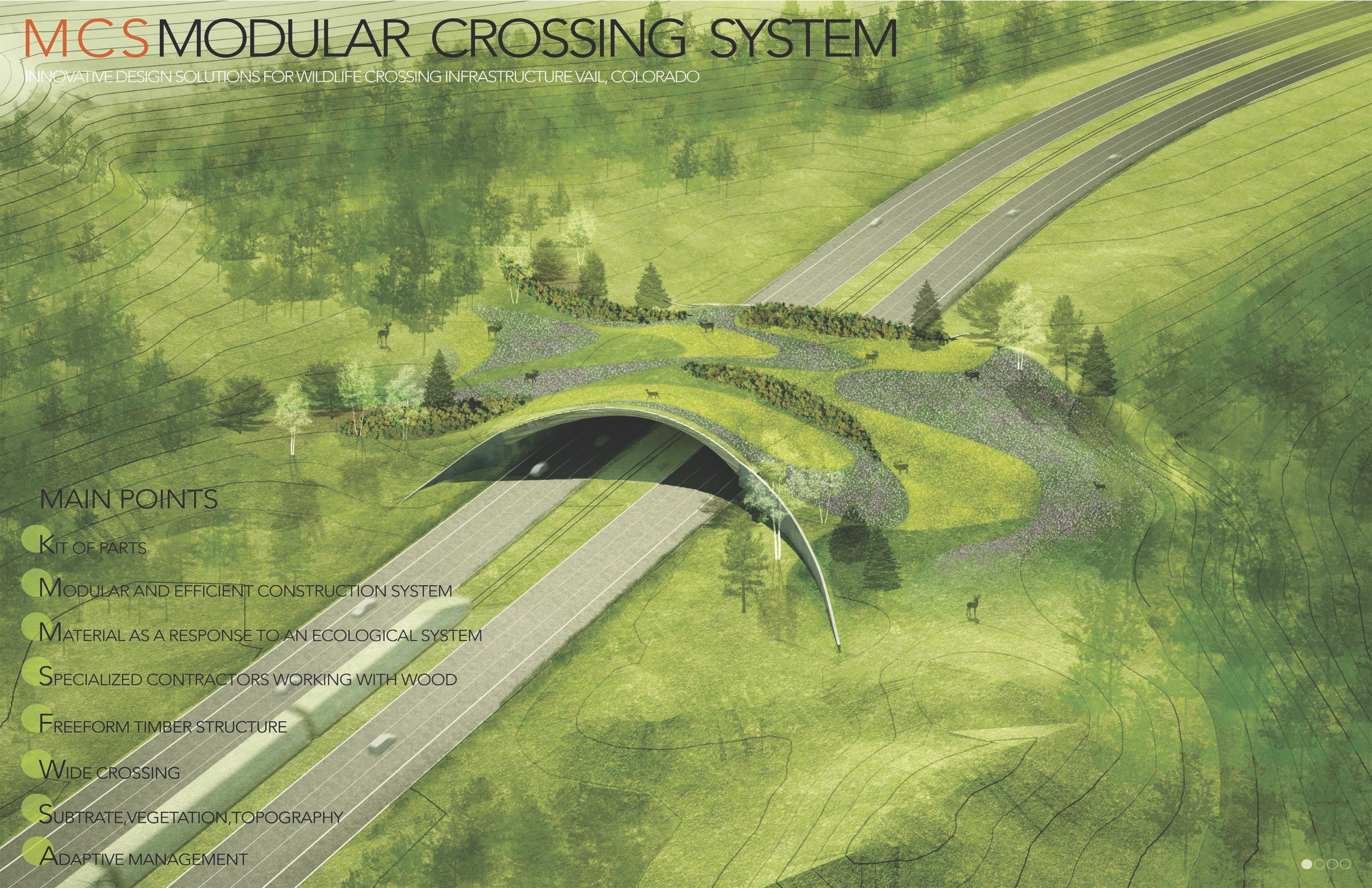

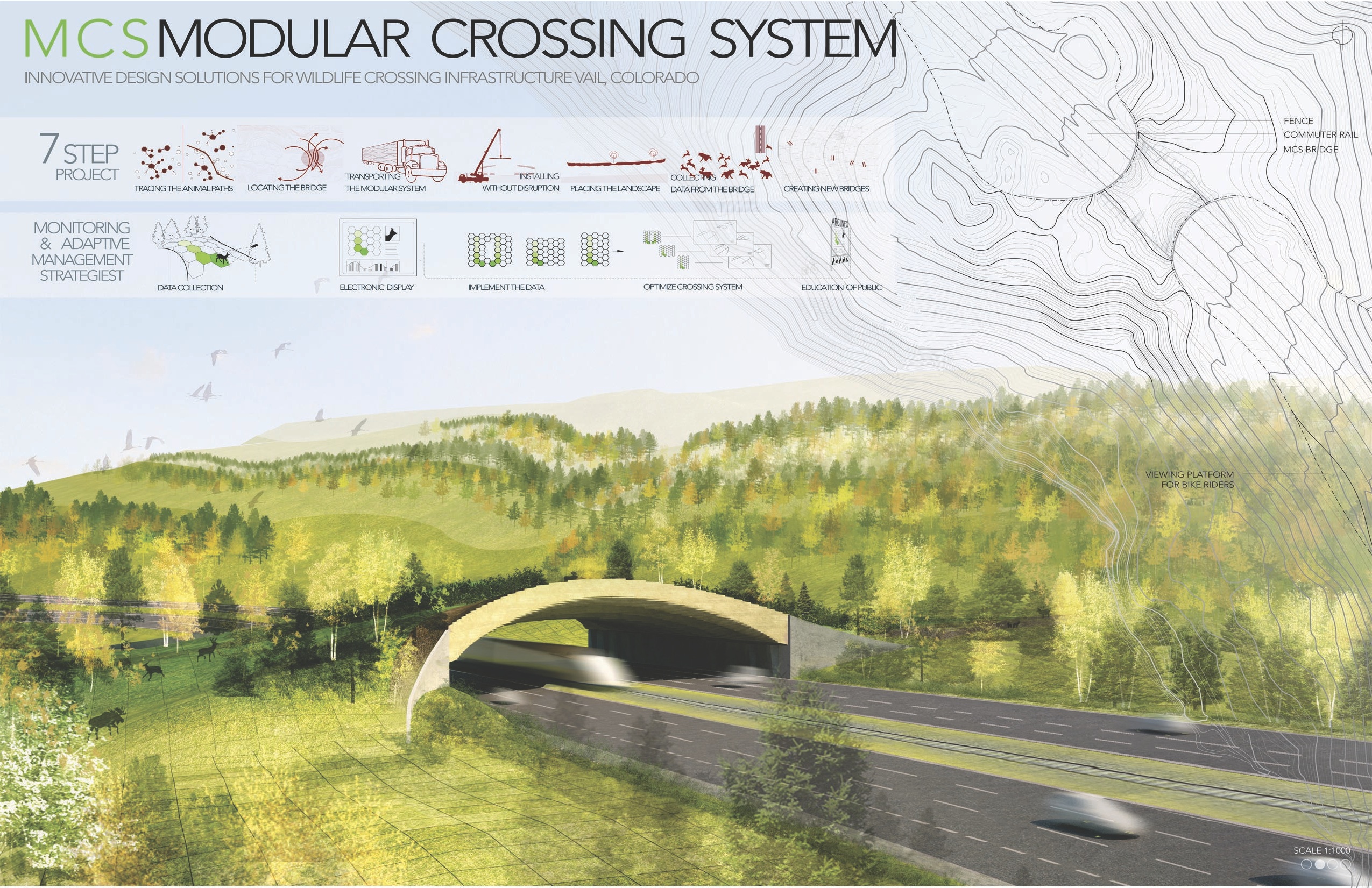

This means that crossing structures could be designed differently from conventional bridge structures. They might include lighter, flexible and adaptive materials or a system of construction that is modular or even dynamic.

These innovations can result in more sustainable and affordable construction. An adaptable, modular structure can also expand, contract or be moved to respond to changing habitats and uncertain climate conditions that are difficult to predict.

As a new category of infrastructure, wildlife crossings are an opportunity to explore new materials, features and approaches to building and construction. This exploration is important, given the diversity of habitats and wildlife species that must be accommodated affordably and safely.

The five finalist teams in the ARC International Design Competition did just that kind of exploring. Their creative, collaborative and interdisciplinary design processes resulted in an innovative range of ideas:

- The concept designs employ a wide diversity of building materials, including glued laminated timber, steel, Ductal concrete (which is more compressive and resistant), glass-reinforced plastic and wood-core fiberglass, as well as more innovative usage of everyday materials such as precast concrete.

- Several designs incorporate layered construction techniques; for example, using stacked convex and concave “arcs,” or steel lattice with modular landscape inserts.

- Others are based on an inverted arc shape, which conveys the feeling of a valley for animals and results in more light for drivers and the roadway; pillar-free designs improve highway safety.

- Designers were asked to include viewing platforms for the public. These range from highway pullouts at a safe distance to a “periscope” for discreet observation that is integrated into the bridge structure.

- All the designs explored the notion of modularity. Some concepts can extend the crossing span or width through landscaped ramps or a structural system of pieces that appear to snap together. Another is based on prefabricated, pre-vegetated habitat modules that respond to local conditions. In all cases, modules can be added or removed as needed and can be switched out if local habitat conditions change. Modular designs and flexible structural solutions ensure efficient construction that saves time and is easy to build without highway closures, or with limited interruption of traffic.

- The designs all accommodate real-time monitoring of wildlife movement for both scientific and public educational purposes through various design features. These include placement of cameras on the bridge that will download to smartphone apps, websites, information kiosks or local schools. Monitoring strategies are designed to permit adaptive management of vegetation and habitat—and in several cases, adaptation of the structure itself.

Snapshots of the five finalist design concepts in the ARC competition offer tangible examples of what is possible in various contexts and circumstances:

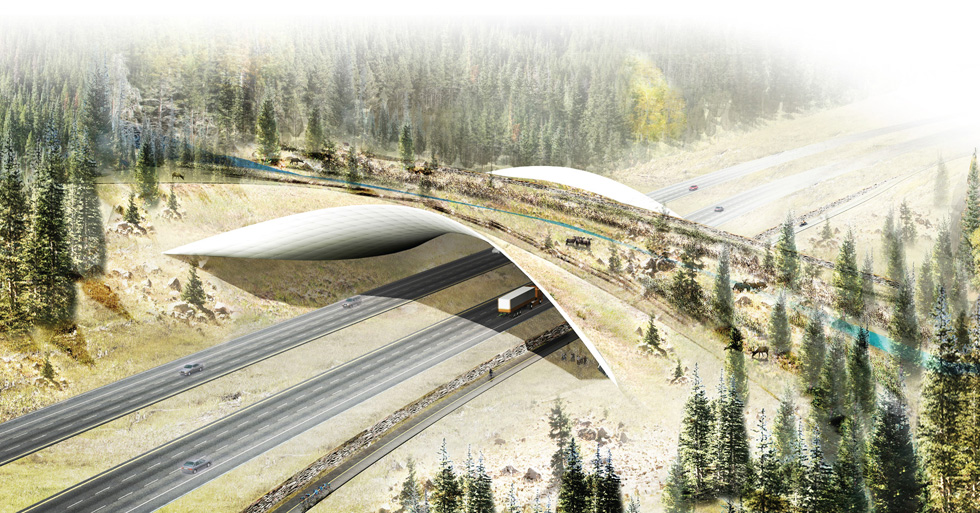

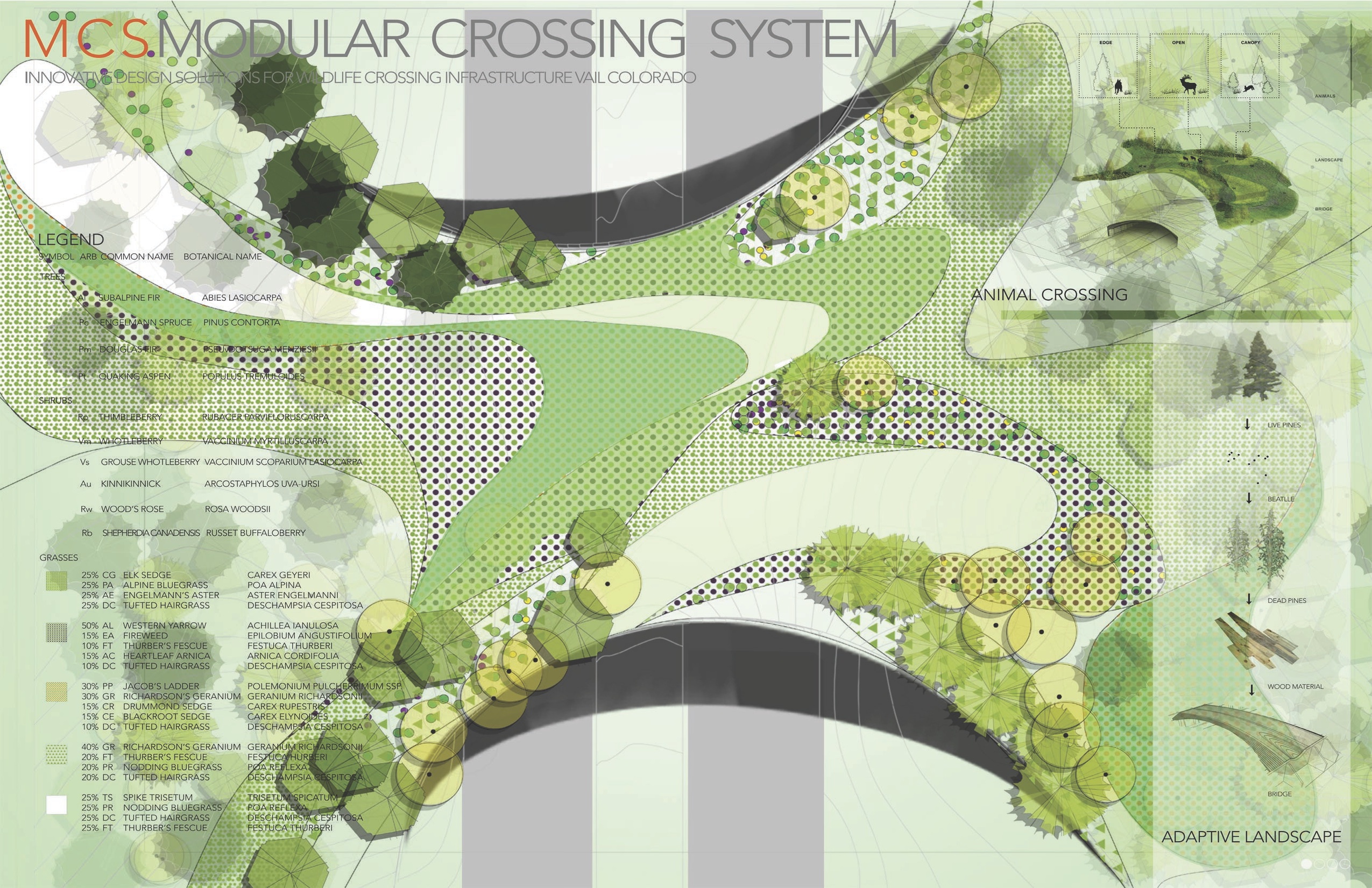

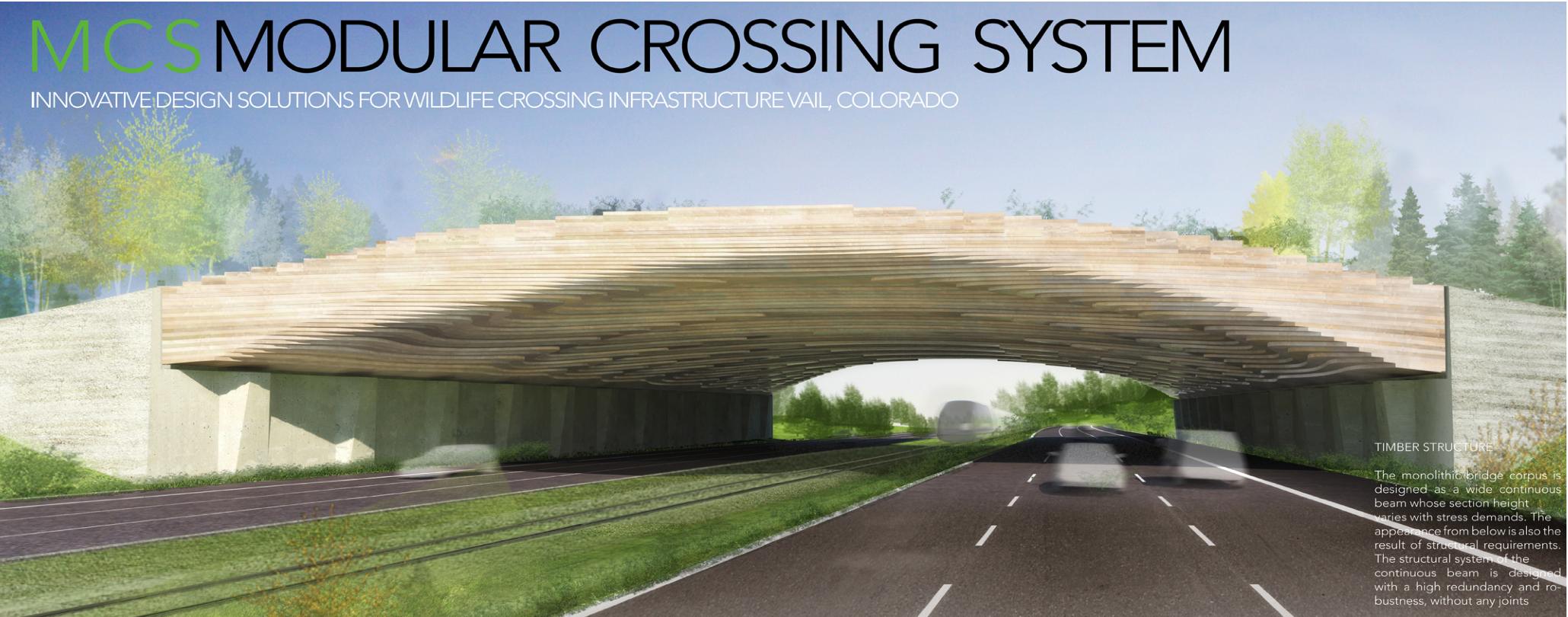

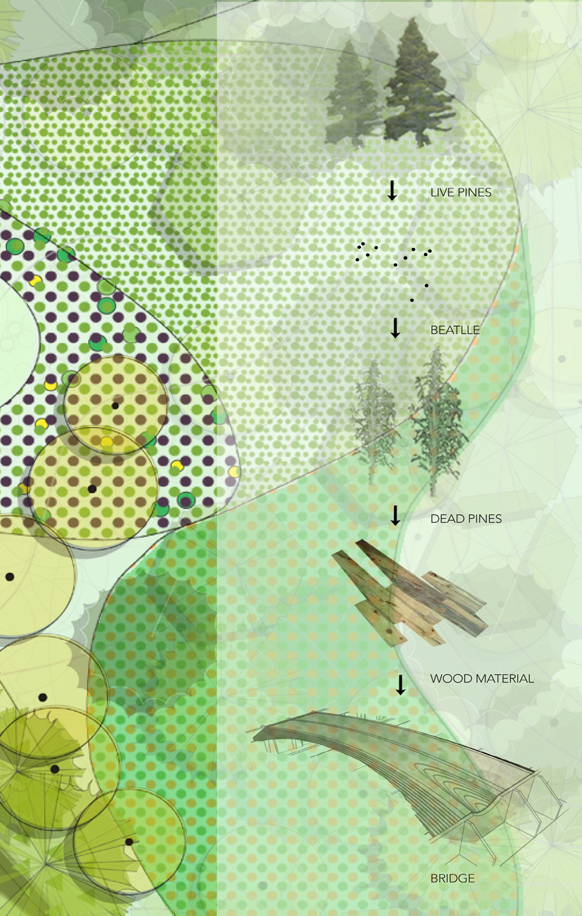

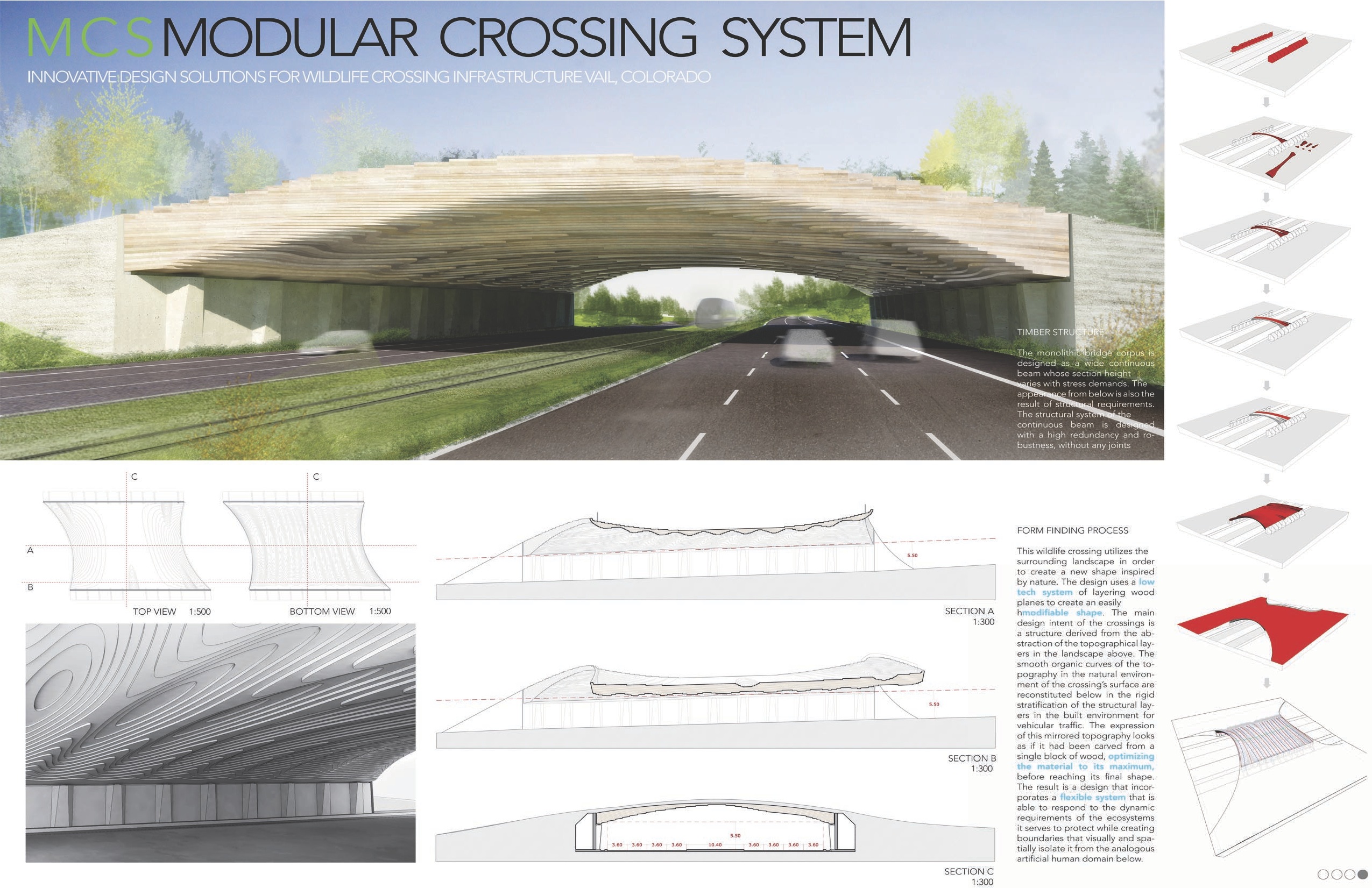

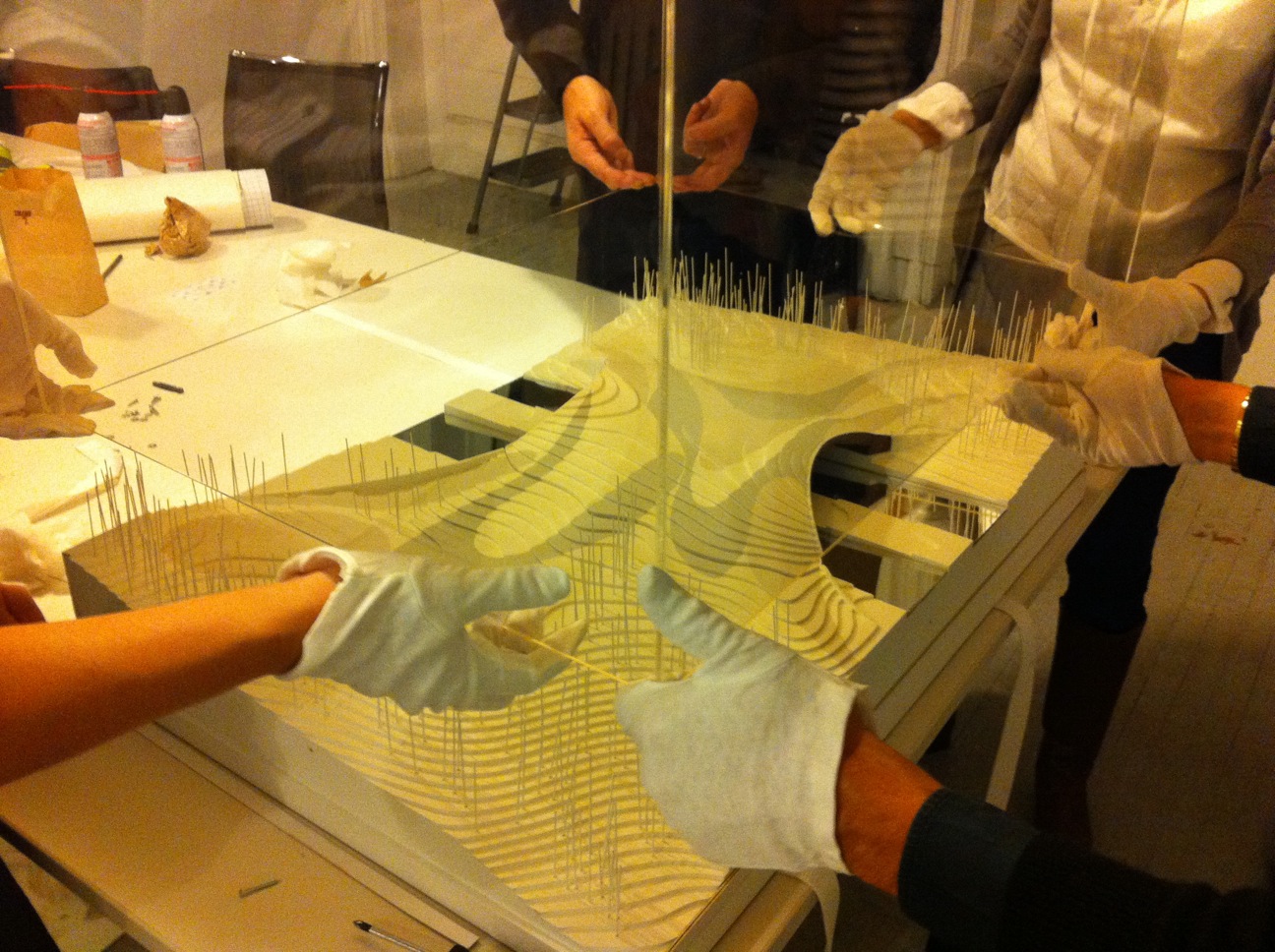

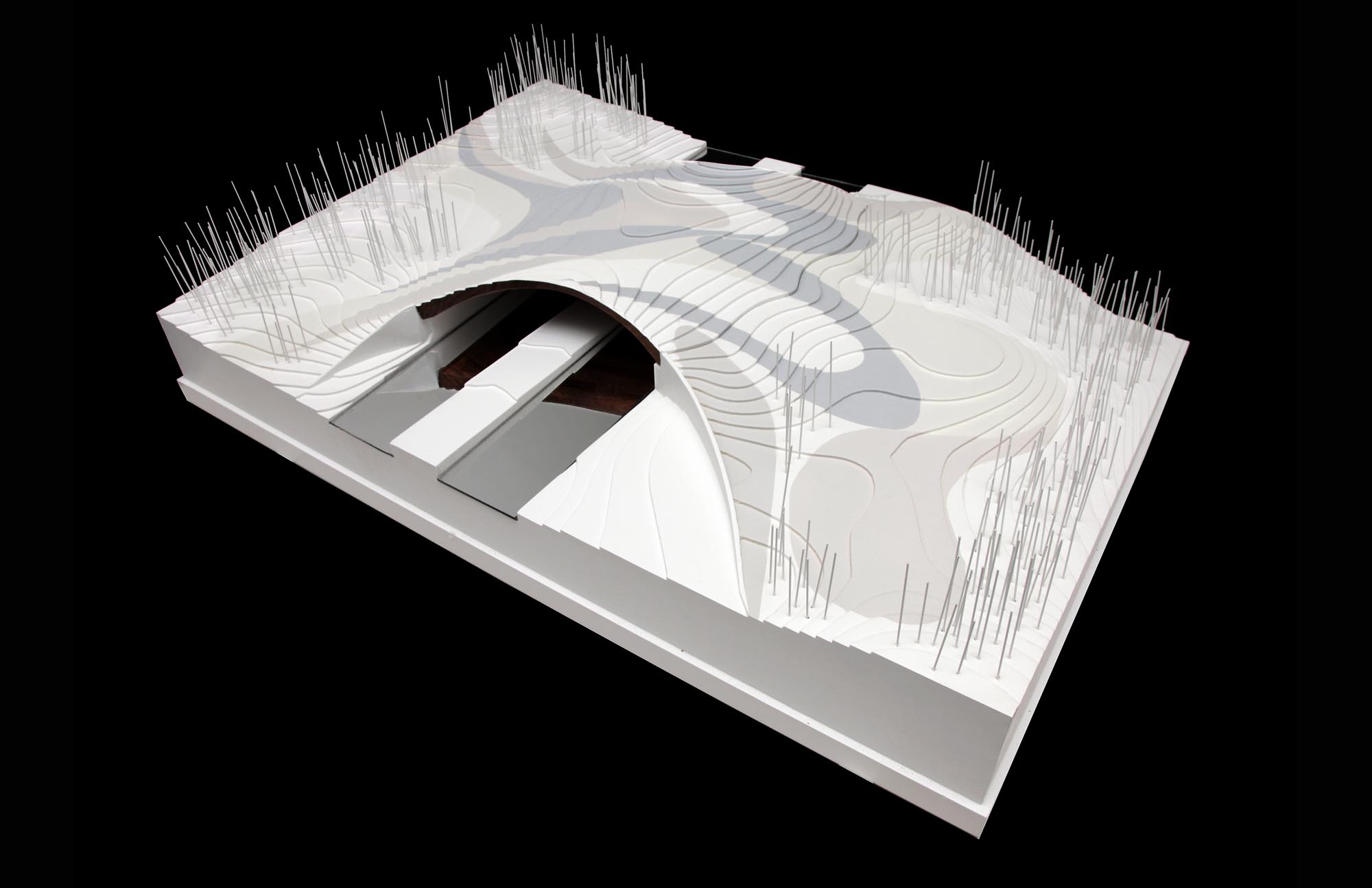

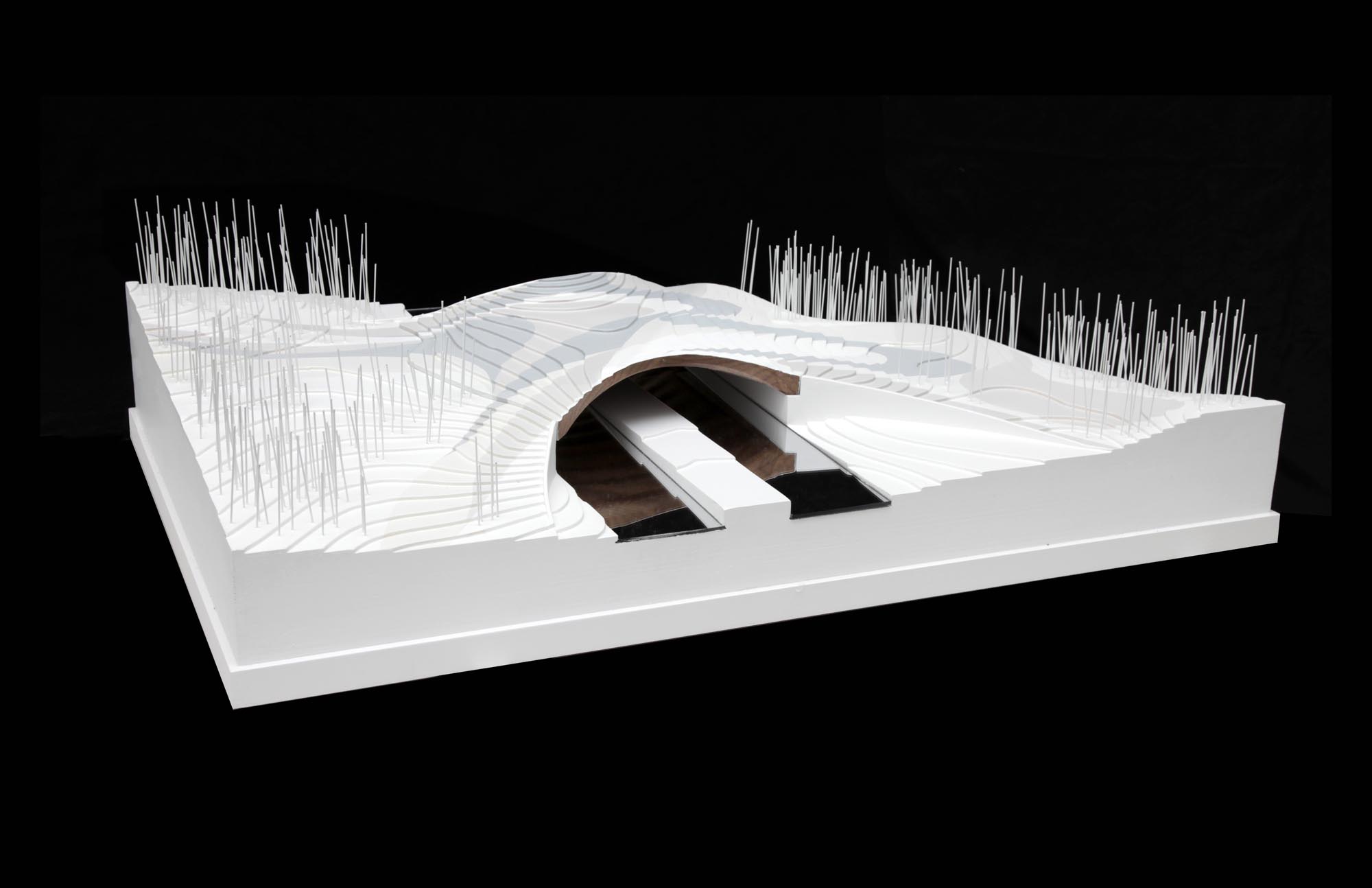

Modular Crossing System

The goal of this design is to create a modular and efficient “kit of parts” using sustainable materials. To achieve this, the design strategy specifies using locally manufactured, laminated timber girders made from timbers killed by the pine beetle. The resulting bridge is a sustainable free-form structure that stores more CO2 than was used in the manufacturing process. The topography of the local landscape is reflected in the underside contours of the structure, while the surface habitat, with its wide ramps, is designed to blend seamlessly into the surrounding landscape

Wild X-ing

[ARC_gallery 1394]The goal of this design is to create a modular structure that can be locally assembled and adapted as habitats change. To achieve this, the design strategy creates a double-curved inverted arc structure, composed of a steel and Ductal grid overlaid with a rhomboid-shaped micro-grid lattice. The lattice is composed of pre-vegetated, lightweight, glass-reinforced plastic habitat modules—inserts that can be adapted, replanted, replaced or expanded as conditions dictate. Customized to local habitat conditions, the modules can be planted off-site and readily transported by flatbed trailer to the site for insertion or replacement.

RED / Research Evolve Design

[ARC_gallery 1399]The design goal for this concept is to build a lightweight, flexible structure that is at once iconic yet almost invisible. To achieve this, the design strategy involves using lightweight, resilient wood-core fiberglass for the bridge structure, which is designed in flexible, modular configurations, or “strands” in the landscape. This strategy makes use of the existing tree canopy as additional habitat between strands and proposes multiple connections into the site with varied possible routes across the bridge, based on the travel habits and preferences of each target species. Notably, the bright red bridge is intended to be an iconic structure for humans, signifying the crossing, the landscape and its non-human inhabitants, but is at once unremarkable to wildlife that cannot see the colour red.

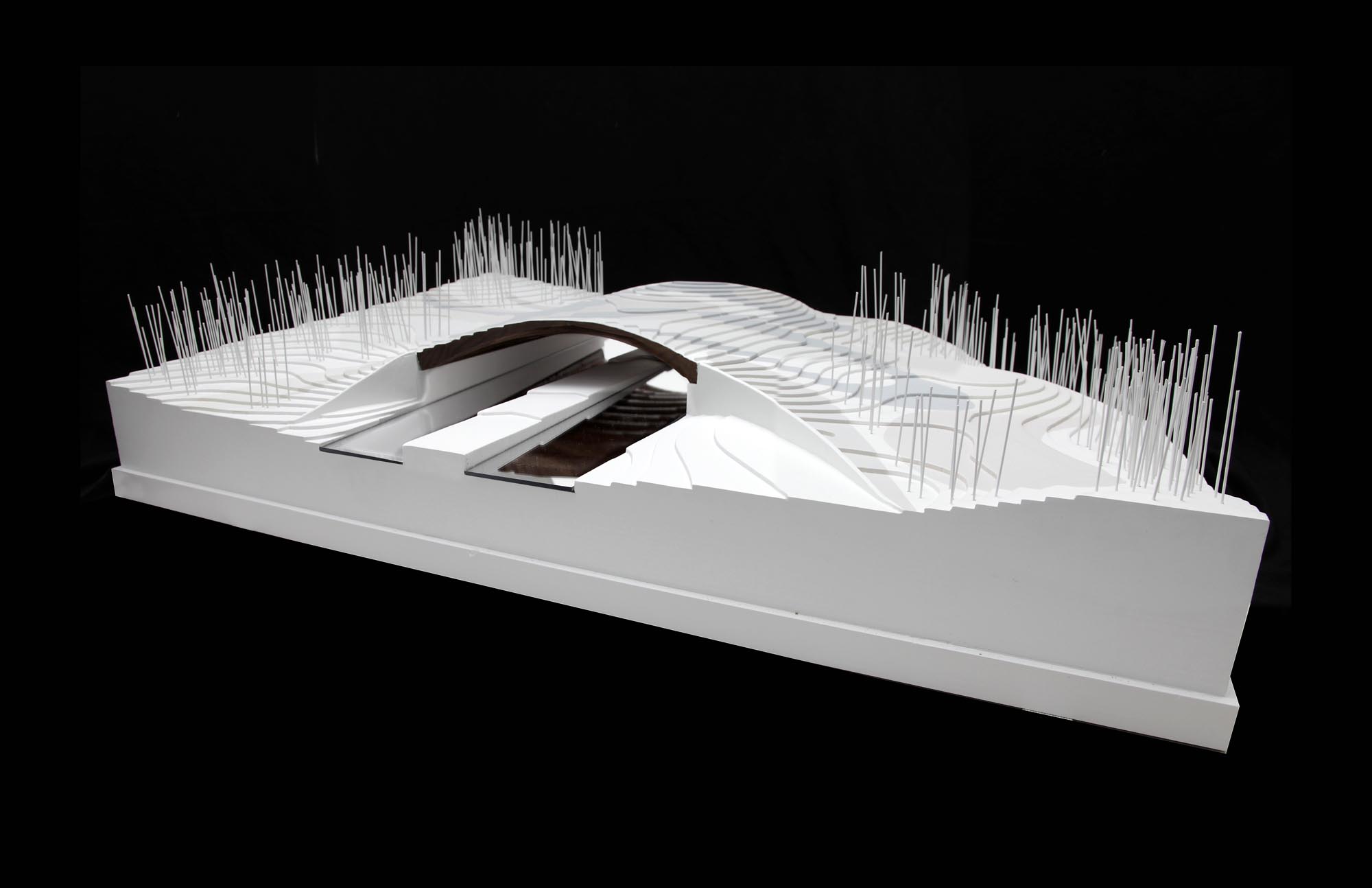

Landshape

[ARC_gallery 1403]The goal of this scheme is to create a cost-effective, lightweight, pillar-free structure that appears to float across the highway. To achieve this, the design strategy involves using concrete formwork to create a thin-shell, double-curved, pillar-less structure. The formwork can be reused many times, and results in a cost-effective structure due to the thin layer of concrete required and the intention of repetitive construction to create a series of bridges. The upper curve of the “landshape” contains the habitat for the crossing, including a system of ponds to serve as a draw for wildlife.

Hypar-Nature

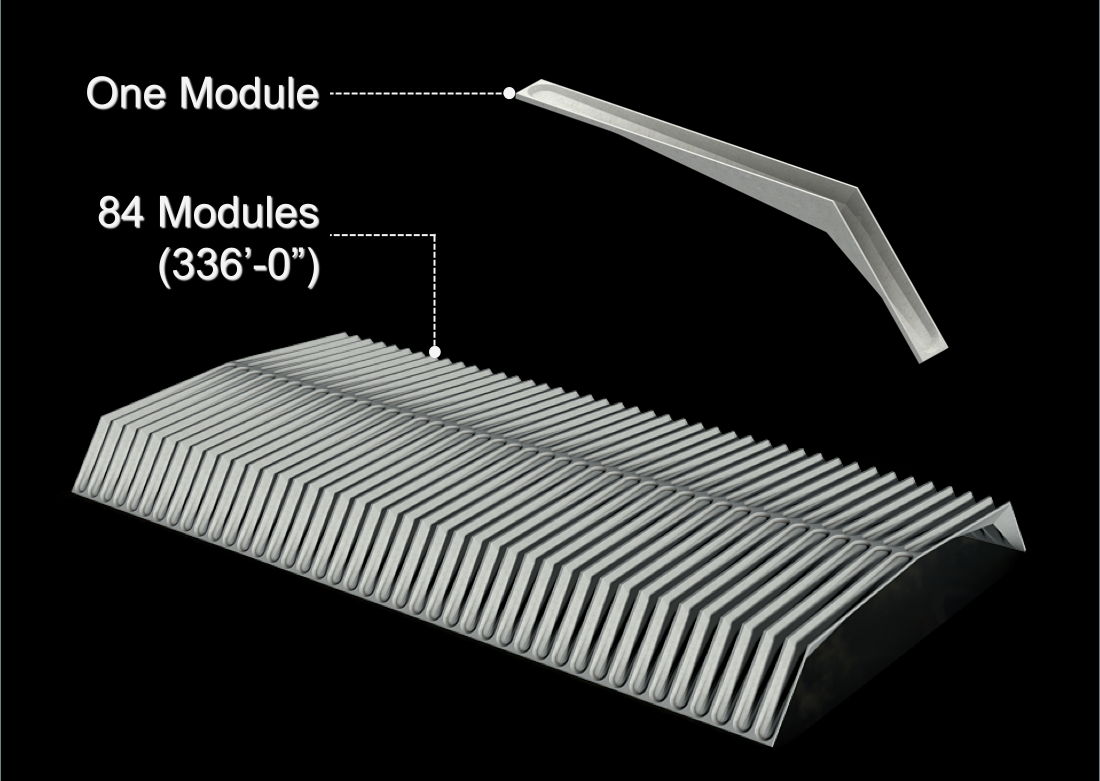

[ARC_gallery 1407]The design goal for the winning design in the ARC competition is to develop a sustainable, modular, flexible, cost-effective crossing system that appears to weave over and under the road, and that can be made locally and assembled on site. To achieve this, the design strategy employs thin-shell, precast, concrete forms based on a three-hinged arch. These hypar-forms allow for minimal site disturbance and relatively easy on-site assembly and deployment, given the widespread availability of local precasting facilities across North America. The hypar-forms can be readily expanded or adapted as wildlife movements and habitats change, or as site-specific conditions dictate. The scheme is a landscape and structural collaboration, bridging both under and over the road, effectively layering both the drivers’ experiences and animals’ preferences.

What’s new about the winning design?

The only way to solve the problem of vehicle-wildlife collisions for good is to have a system of crossing structures—overpasses and underpasses, bridges and tunnels. No single structure alone will solve more than a localized problem. ARC’s goal is to make wildlife crossings a ubiquitous part of the North American roadscape. To do this, an adaptable, flexible and modular design is needed—one that can be readily modified to different contexts and circumstances.

One of the simplest and most elegant ways to begin this infrastructural transformation is to use everyday materials that are readily available, but to use these materials in an uncommon and modular way. This is precisely what the winning team proposed.

Designed by HNTB with Michael Van Valkenburgh Associates Inc., the winning concept for the ARC competition demonstrates how a reliable, predicable and proven material can be deployed in an uncommon or novel way. Precast concrete is one of the most common building materials in North America, meaning that every state has the capability to make precast concrete and no location in the U.S. is more than 250 miles (400 km) from a fabricating plant. Although concrete is not considered a sustainable material, there are improvements being made in its composition. Precast concrete is readily available to use on a large scale, in many locations, which lowers the production cost for the crossing structures.

Over time, as wildlife crossing structures become more commonplace, the public sector may be more willing to take risks with new materials and embrace more experimentation in different contexts and applications. In the immediate future, ARC’s goal is get several prototypical structures built and to demonstrate to state and federal agencies and to the public at large that these crossings work. They will reduce animal-vehicle collisions between 80 and 100 per cent if designed correctly; with time, wildlife crossings can eliminate the problem and the cost of such collisions.